The Product

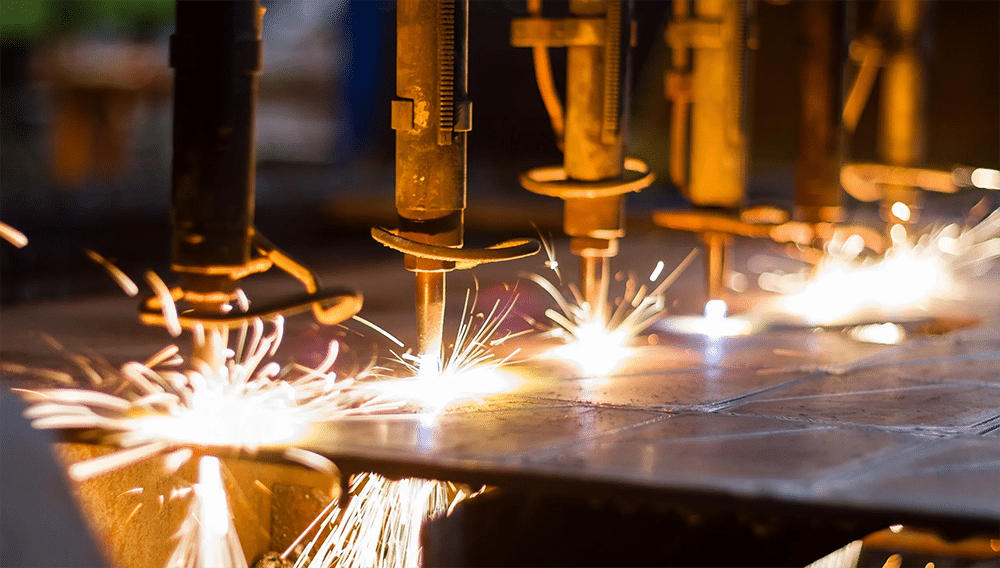

Direct Energy Deposition at point of use without a need for prefabrication and transport with capability to do custom and complicated shape coatings. This platform enables on-demand manufacturing in remote and challenging locations while maintaining superior quality comparable to parts produced in a laboratory.

Our Mission

At Mand-Tech, we are redefining the future of manufacturing with our proprietary MAND technology equipment. Our innovative platform enables precise, sustainable, and scalable production of nanostructured materials tailored to any shape or application. Designed for point-of-use deployment, our technology eliminates the need for traditional transportation and storage, reducing environmental impact while enhancing efficiency. Whether for advanced industries or everyday applications, we empower businesses to create high-performance materials exactly when and where they need them. Welcome to the future of decentralized, sustainable manufacturing.

We can partner with 3D printing manufacturers, additive manufacturing companies, and aerospace organizations to utilize 3D printers or other direct energy deposition technologies for on-demand production, eliminating the need for prefabrication and transportation.

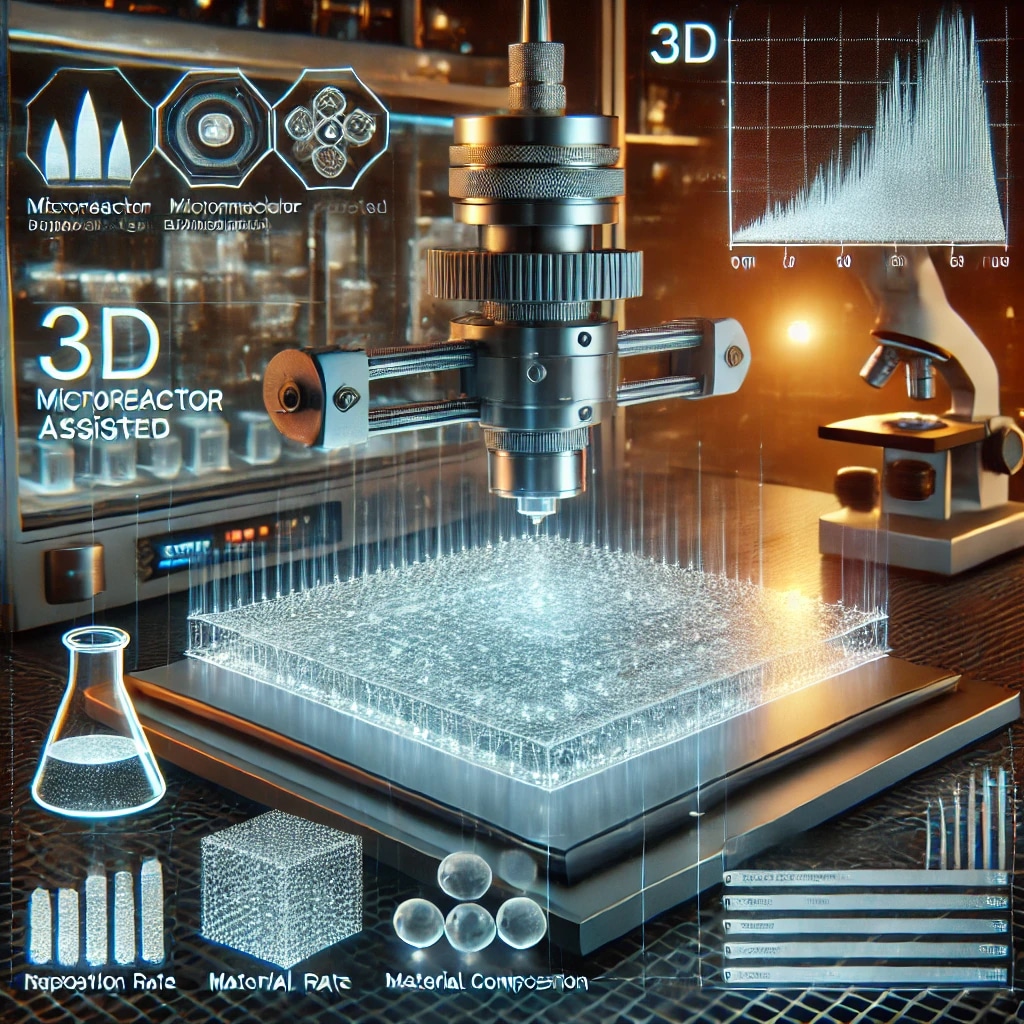

Technology

Microreactor-Assisted Nanomaterial Deposition (MAND) is a promising platform for nanomaterial synthesis that controls growth and nucleation parameters through in-situ generation of reactive fluxes and nanomaterials to deposit nanostructured materials with distinct morphologies, structures, and properties at the point of use.

Microreactor technologies offer large surface-area-to-volume ratios to accelerate heat and mass transport, allowing for rapid changes in reaction conditions and more uniform heating and mixing. It overcomes the scale-up barrier via process intensification and provides precise control over heat, mass, and momentum transport using well-defined microstructures of the reactor cell that can be numbered up at large scales.

The ability to synthesize nanomaterials in precise volumes at the point of interest eliminates the need to store and transport potentially hazardous materials and leads to low material waste and footprint that is valuable to achieve sustainable manufacturing.

Use Cases

Printed Electronics

Direct fabrication of highly conductive traces at room temperature without post-processing, ideal for flexible electronics, RFID tags, and wearable sensors.

Metal 3D Printing

Reactive dry printing and nanoparticle-fused additive manufacturing produce next-generation metal matrix composites, improving mechanical properties, heat resistance, and energy efficiency for medical device and other industrial applications.

Defense & Aerospace

The additive manufacturing of oxide dispersion-strengthened (ODS) alloys enhances high-temperature strength, oxidation resistance, and creep resistance.

Who We Are